What Are the Latest Innovations in Bulk Bag Unloading Technology?

In the rapidly evolving landscape of industrial material handling, bulk bag unloading technology has undergone significant advancements. These innovations are not just enhancing efficiency but are also addressing the nuanced demands of various industries. In this article, we delve into the latest breakthroughs in bulk bag unloading technology, revealing how these advancements are reshaping manufacturing processes.

Automation

One of the most noteworthy advancements in bulk bag unloading is the integration of automation. Automated systems have revolutionized the bulk unloading process, offering unprecedented precision and consistency within manufacturing. These systems are equipped with sensors and programmable logic controllers (PLCs) that allow for real-time adjustments, ensuring all materials flow smoothly and reduces manual intervention. This shift towards automation not only boosts productivity but also significantly minimizes the risk of human error and enhances workplace safety.

Enhanced Dust Control

Dust control has always been a critical concern in bulk bag unloading. The latest systems come with advanced dust containment features, such as improved sealing mechanisms and integrated dust extraction units. These innovations ensure a cleaner and safer work environment, especially crucial when handling hazardous or sensitive materials. By effectively managing dust emissions, these state-of-the-art unloaders are setting new standards in environmental compliance and operator safety.

Customization & Flexibility

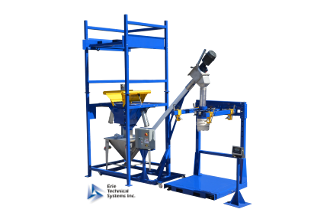

The adaptability of bulk bag unloaders to various operational needs is another area where innovation shines. Modern unloaders offer unparalleled customization, catering to a wide range of material types, bag sizes, and unloading rates. Features like adjustable frames, modular designs, and a variety of discharge options underscore their flexibility. This level of customization ensures that businesses can tailor their unloading systems to their specific requirements, be it in food processing, pharmaceuticals, or construction materials, maximizing both efficiency and cost-effectiveness.

Integration with IoT and Data Analytics

Integration with the Internet of Things (IoT) and data analytics is a game-changer in bulk bag unloading technology. IoT-enabled systems provide real-time data monitoring and analysis, facilitating predictive maintenance and operational insights. This connectivity allows for better tracking of material usage, system performance, and even helps in identifying potential issues before they escalate, ensuring continuous improvement in material handling processes.

The latest innovations in bulk bag unloading technology are pivotal in transforming manufacturing and material handling landscapes. As these technologies continue to evolve, they promise to bring even greater efficiency, safety, and customization to the forefront of industrial operations. If you are looking to add an innovative bulk unloading system to your process - contact Erie Technical Systems to learn about your options.