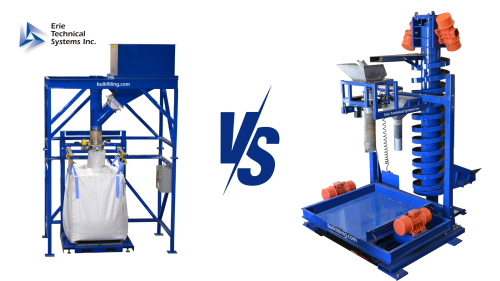

Choosing the right bulk bag filler is important to your manufacturing process, but it doesn't have to be complicated. Erie Technical Systems Inc. offers two distinct budget-friendly options: the ValuMAX® and the DensiMAX™ bulk bag fillers. Each has unique features and advantages, making them suitable for different applications. We outlined the specifics of these bulk bag filling systems to help you decide which is the best fit for your needs.

ValuMAX® Bulk Bag Filler: Simplicity and Cost-Effectiveness

The ValuMAX® bulk bag filler is designed for simplicity and cost-effectiveness. With its heavy-duty structural steel construction, it offers durability without breaking the bank. The 2-post design allows for easy front access, making it quick to remove filled bulk bags with a forklift. It's adjustable to accommodate a range of bulk bag sizes and can support up to 2,500 pounds of product.

Key Features:

- 2-post open-front design for easy removal.

- Adjustable arms for various bulk bag sizes.

- Supports up to 2,500 pounds.

- Optional manual additions like weigh scales and slide gate valves.

Typical Applications:

- Dust collector by-product bagging

- Dry bulk solids

- Aggregates

- Process by-products

- Food handling

DensiMAX™ Bulk Bag Filler: Automation and Precision

The DensiMAX™ Bulk Bag Filling Station takes automation and precision to the next level. With PLC control, this semi-automated system can fill, vibrate, and weigh bulk bags, FIBC's, IBC's, and more. Its design focuses on operator-friendly features and heavy-duty construction, ensuring reliability even in demanding plant atmospheres.

Key Features:

- Semi-automatic operation with PLC control.

- Simultaneous weigh, fill, and densify processes.

- Can increase material packaging by up to 50%.

- Modular construction for future upgrades.

- Easily integrates with existing processes.

- Customizable controls and operations.

Typical Applications:

- High-volume bulk material handling

- Situations requiring precise weight measurements

- Industries needing to maximize container space

Both the ValuMAX® and DensiMAX™ bulk bag fillers offer unique advantages. The ValuMAX® is ideal for businesses looking for a simple, cost-effective solution for various bulk materials, including food and aggregates. On the other hand, the DensiMAX™ is perfect for operations requiring a higher level of automation, precision, and the ability to densify materials for more efficient packing.

Ultimately, the choice between ValuMAX® and DensiMAX™ depends on your specific bulk bag manufacturing and handling needs. Consider factors like the level of automation, material type, and budget when making your decision. For more information or assistance in selecting the perfect conveyor for your needs, don't hesitate to contact the team at Erie Technical Systems.