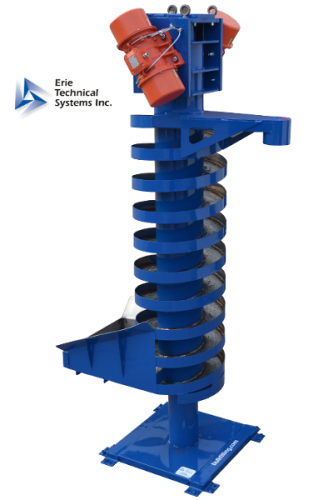

UNDERSTANDING VIBRATORY SPIRAL ELEVATORS

The vibratory spiral elevator operates like a horizontal vibratory feeder, using rotary electric vibrators to create a linear reciprocating force over 2G. This force throws material forward and then retracts while the material is airborne, conveying it efficiently. Operating at frequencies between 900 and 1800 RPM, it depends on the product. The conveyor trough, shaped as a spiral and welded to the central drive tube, directs the material upward with specific drive angle and trough pitch for efficient movement.

ADVANTAGES

- The vibratory spiral elevator provides a streamlined path for material travel, significantly reducing product damage, contamination, or leakage.

- It features a compact footprint, making it ideal for application with limited space.

- Its smooth surfaces facilitate easy product changes.

- The elevator is designed for easy cleaning.

- Maintenance requirements are minimal, with only two rotary electric vibrators and isolators subject to wear.

CONCLUSION

Vibratory Spiral Elevators are versatile and low-maintenance machines ideal for conveying material. They are easy to clean, save space, and fit into tight areas, eliminating the need for redesigning your process.

Erie Technical Systems offers free product testing in our lab. Please contact us at info@erietechnicalsystems.com or call us at 814-899-2103 and let one of our experts help with your application.