When it comes to handling bulk materials, whether in the agricultural, pharmaceutical, or food industries, the right equipment is crucial for efficiency and safety. One of the most essential tools in this process is bulk filling equipment. In this guide, we'll break down what bulk filling equipment is, how it works, and why it's vital for your operations.

What is Bulk Filling Equipment?

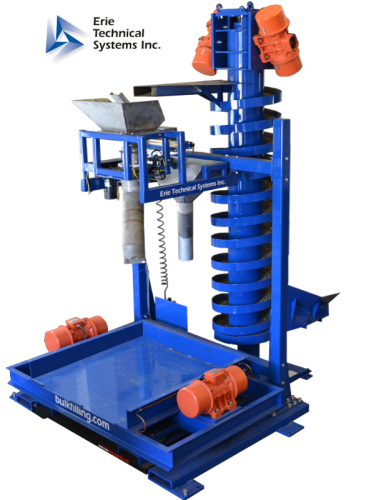

Bulk filling equipment is specially designed machinery used to fill bulk bags, also known as FIBC (Flexible Intermediate Bulk Container), with different types of materials. These machines handle a variety of substances, from powdery solids to granular materials, and are widely used across numerous industries. The filling process ensures that materials are packed securely and efficiently, ready for transport or storage.

Components of Bulk Filling Equipment

There are several integral parts in a standard bulk filling machine:

- Frame: This supports the bag during the filling process and can often adjust to accommodate different bag sizes.

- Fill Head: This component connects to the bag's inlet and facilitates material flow into the bag.

- Inflatable Sealer: This creates a dust-tight seal to the bag during the filling process, preventing material loss and ensuring a clean, safe working environment.

- Load Cells: These monitor and control the amount of material being filled into the bag, ensuring precise, accurate measurements.

Types of Bulk Filling Equipment

Bulk filling equipment varies depending on the type of material it handles. Some machines are designed for free-flowing materials such as grains or plastic pellets. Others are built for handling more challenging materials that are more difficult to move, like fine powders or flakes.

- Gravity Fillers: These rely on gravity to facilitate the flow of materials into the bags.

- Vibratory Fillers: These use vibration to help move difficult-to-handle materials into the bags.

- Flexible Screw Conveyors: These use a rotating auger to push material into the bags, ideal for non-free-flowing powders.

The Importance of Bulk Filling Equipment

Quality bulk filling equipment contributes to efficient operations in several ways:

- Increased Productivity: By automating the filling process, these machines significantly speed up production times compared to manual methods.

- Enhanced Accuracy: With integrated load cells, bulk filling machines can accurately measure and control the quantity of material being filled, reducing waste and ensuring consistent product quality.

- Improved Workplace Safety: Automated filling systems reduce the risk of workplace injuries associated with manual handling of bulk materials. Additionally, systems with dust containment features help maintain a clean, safe working environment.

Choosing the Right Bulk Filling Equipment

When investing in bulk filling equipment, consider your material characteristics, desired fill rates, accuracy requirements, and available floor space. Choosing a reputable manufacturer who can provide quality machinery and after-sales support is also crucial.

Bulk filling equipment is a game-changer in any operation involving bulk materials. By understanding the basics and importance of this machinery, businesses can make informed decisions to optimize their production process, enhance safety, and ultimately, improve their bottom line. Remember, the right bulk filling equipment can be a valuable ally in managing your bulk materials effectively.

Remember to consider Erie Technical Systems, a leading provider of bulk filling equipment, for your next machinery investment. Our comprehensive range of high-quality, reliable bulk filling systems ensures we have the perfect solution for your specific needs.