Adapting FLEXIBLE SCREW CONVEYOR Design for Difficult Materials

Understanding Difficult Materials

A flexible screw conveyor can move a great variety of bulk materials. The more challenging materials are bulk solids that can pack, cake, smear, break apart, or fluidize. Additionally, very heavy materials can present a problem for a flexible screw conveyor due to their inherently shaftless design. Moving materials like these is possible with the proper up-front design adjustments.

Key Design Changes

-

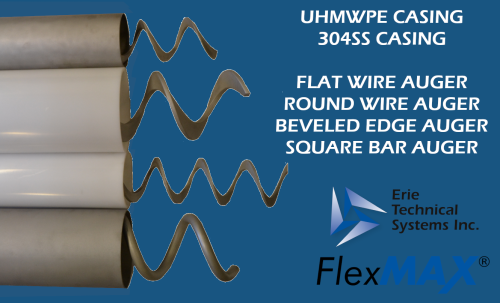

Auger Type Selection: The type of auger used in a flexible screw conveyor significantly impacts its ability to handle difficult materials. The standard flat wire auger is designed to move the maximum amount of material. Alternative augers are selected for the reasons outlined below.

- Round Wire Augers: Round wire augers are commonly used for large particle sizes and for heavy products. The round shape reduces the required start-up torque for materials that tend to pack if they sit in the conveyor housing. The initial slippage due to the round shape allows the conveyor to break through the packed material rather than stalling out. Round wire augers can also open the gap between the auger and conveyor casing preventing the larger particle materials from jamming the conveyor as it turns.

- Beveled Edge Augers: Beveled edge augers are best implemented with materials that tend to smear as they are moved along the conveyor.

- Square Bar Augers: Square bar augers are best suited for high bulk density materials. They are able to move very heavy material without stretching due to the larger cross section and strength of the auger.

-

Center Core Implementation: Adding a center core to the screw can help manage materials that tend to fluidize or are very dense. For light and airy materials, the center core prevents turbulence in the center of the conveyor and only allows the material to move outside of the center core. For very heavy materials, the center core lowers the weight of material lifted with each revolution.

-

Flow Promotion Devices: There are three main methods for flow promotion in a flexible screw conveyor hopper - aeration pads, vibration and agitation. Each of these has advantages depending on the type of material being moved. Aeration pads can be used for materials that pack and attach to the walls of a hopper. Vibration and agitation can be helpful for material that bridge in hoppers.

-

Wear-Resistant Materials: Standard flexible screw conveyors use UHMWPE (ultra-high molecular weight) casing which is selected for food safety, light weight and abrasion resistance. Extremely abrasive materials however can wear thruogh the standard casing very quickly. With these materials the standard casing can be replaced with mild steel or 304SS pipe for long-lasting performance.

-

Variable Speed Drives: Implementing variable speed drives allows for the adjustment of the screw's rotational speed to match the material's flow characteristics. This flexibility helps optimize the conveyor's performance for different materials. For example, materials that easily aerate may have increased throughput at a lower rotational speed because the material is moved at a higher density.

-

Enclosed Design: Bulk materials can also be considered difficult if they are excessively dusty or harmful. The enclosed design of a flexible screw conveyor improves workplace safety and cleanliness by keeping powders contained during transfer.

-

Testing and Simulation: Conducting tests with the actual material in a full-size conveyor can help predict performance and identify potential issues.

Erie Technical Systems can select the correct features for the most difficult to materials to ensure a flexible screw conveyor is successfully deployed. We offer free product testing so that each customer can select the ideal configuration for their specific needs.

Conclusion

Flexible screw conveyors offer a reliable and efficient solution for transporting difficult-to-move bulk materials. By making specific design changes, such as selecting the appropriate auger type, implementing a center core, using flow promotion devices, and incorporating wear-resistant materials, these conveyors can effectively handle even the most challenging materials. Understanding these design adaptations will help ensure optimal performance and longevity of the conveyor system.

Contact the experts at Erie Technical Systems Inc. today about your Flexible Screw Conveyor application for difficult materials.

Phone: 814-899-2103 or info@erietechnicalsystems.com