Case Study: Innovative Solution for Rubber Recycling with Erie Technical Systems Inc.

Client Overview

Erie Technical Systems Inc. recently collaborated with a world leader in recycled rubber manufacturing based in the Midwest. The client specializes in processing recycled EPDM rubber, turning it into high-quality pellets for various applications.

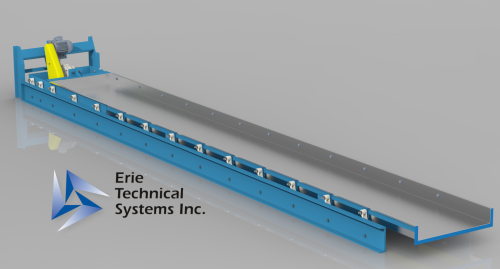

Erie Technical Systems Inc. recently created a large vibratory pan arm conveyor to convey rubber pellets for a world leader in recycled rubber manufacturing, located in the Mid-West. The conveyor was designed to transfer recycled EPDM rubber after it is washed and shredded into the downstream process. The conveyor was designed to spread the material and slowly convey it to allow water to leave the surface of the rubber. A vibratory conveyor with shaker drive and pan arm construction was selected for the application to deliver the desired feed rate of 3.25 tons/hour (2,950 kg/hr).

Challenge

The client faced multiple challenges in their manufacturing process:

Slow Feed Rate: The client required a feed rate of 3.35 tons per hour, and the average vibratory shaker drive conveyors move at about 35 feet per minute.

Conveyor Length: The required conveyor length was 25 feet with a width of 36 inches, which is considerably long for the specified width.

Low Profile Requirement: The system needed to integrate with an existing washer with a very low discharge point, complicating the design requirements for the conveyor. Pan-arm style conveyors require a 1.5 or 2:1 ratio of pan weight to base frame weight to function properly.

Solution

Erie Technical Systems Inc. devised a comprehensive solution to tackle these challenges:

Modified Shaker Drive: Erie Technical Systems Inc.'s engineering team addressed the feed rate by sheaving the shaker drive to run at a lower RPM, which reduced the stroke of the vibration. Additionally, a VFD (variable speed drive) was added to the motor to allow further reduction of the shaker speed as needed. A final modification was added to change the angle of the pan arms to reduce the stroke of the conveyor.

Optimized Conveyor Design: The challenge of length was solved by placing the drive mechanism at the end of the conveyor pan rather than on top or bottom. This places the shaker drive force directly behind the conveyor pan and ensures the force being delivered is all in the horizontal direction. This eliminates the whip common in long conveyor pans with a top or bottom-mounted drive.

Weight Adjustments: This end mount drive also allowed for a lower profile for the machine to fit under the washer system at the pick-up end of the conveyor. Weight was added to the base frame to maintain a 1.5:1 ratio of base to conveyor pan.

Results

Through rigorous testing with the client's product, the customized conveyor demonstrated excellent performance across various settings:

- At 60 Hz, achieving a feed rate of 10 TPH at 1" bed depth.

- At 45 Hz, reducing to 5.5 TPH.

- At 40 Hz, further slowing to 4.25 TPH.

These settings proved that the conveyor could operate efficiently between 30-40Hz, meeting the client's requirement for specific residence times and conveying speeds.

Lessons Learned

The project underscored the importance of flexibility and precision in mechanical design, especially when integrating new systems with existing equipment. From working with the customer, we determined that the conveyor could be run at 30-40hz to deliver the desired residence time and conveying speed. The use of a VFD and adjustments to the pan arm angle were pivotal in achieving the desired outcomes.

Conclusion

This case study exemplifies Erie Technical Systems Inc.'s capability to design and implement tailored solutions for complex bulk material handling challenges. Our innovative approach and detailed understanding of client needs allowed us to deliver a system that not only meets but exceeds expectations. For custom-designed solutions that address unique challenges in your production line, contact Erie Technical Systems.

Contact Erie Technical Systems today to explore how we can enhance your material handling processes with customized solutions.