Flexible screw conveyors are vital components in many material handling systems, prized for their versatility and efficiency. However, like any machinery, they can encounter issues. Understanding these problems and knowing how to solve them is key to maintaining an efficient flexible conveyor system. In this article, we delve into five common problems and provide solutions to ensure your automated flexible screw conveyor continues to operate smoothly.

- Wear and Tear of the Screw and Casing.

Over time, the screw in a flexible screw conveyor can wear down, particularly when conveying abrasive materials, leading to reduced efficiency and potential breakdowns. Regular inspection and maintenance are crucial. Opt for a custom flexible screw conveyor designed with wear-resistant materials suitable for the specific types of materials you are handling.

- Material Clogging and Buildup

Materials can sometimes clog or build up within the conveyor, especially if they are moist or sticky, causing blockages and operational delays. We see this issue a lot in the construction and food-processing industries. Implement a flexible conveyor system with easy-clean features and designs that prevent material buildup. Choosing the right screw design and pitch can also significantly reduce the risk of clogging.

- Inconsistent Material Flow

Achieving a consistent flow of materials can be challenging, often due to improper installation or incorrect conveyor setup. Ensure that your flexible screw conveyor is installed correctly with the right angle and speed settings. Automated controls can be beneficial to regulate and maintain consistent material flow.

- Noise and Vibration Issues

Excessive noise and vibration are not uncommon, which can be a sign of mechanical issues or can create a disruptive working environment. Regular maintenance and checking alignment can prevent these issues. Additionally, using conveyors designed with noise-reduction features can be beneficial.

- Limited Conveying Distance and Capacity

Some flexible screw conveyors may have limitations in terms of the distance they can convey materials or their capacity, which can be a bottleneck in operations. When purchasing a conveyor, consider a custom flexible screw conveyor system designed to meet your specific distance and capacity requirements. Multiple conveyors can be linked for longer distances, or consider other types of conveyors for larger capacity needs.

While flexible screw conveyors are an efficient and versatile solution for material handling, being aware of common issues and their solutions is key to ensuring long-term operational success. By choosing the right conveyor design, conducting regular maintenance, and opting for custom solutions when necessary, you can maximize the efficiency of your flexible screw conveyor system.

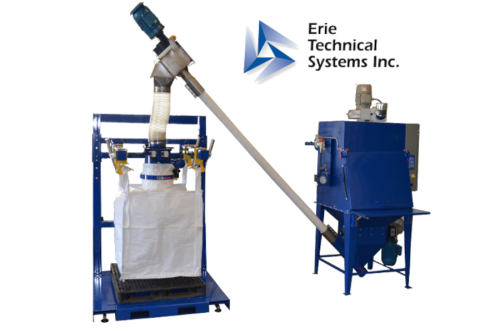

At Erie Technical Systems we have several Flexible Screw Conveyor options available with our FlexMAX product line. Please contact us to discuss you specific application. We also offer product testing in our laboratory to ensure the system you purchase will convey your specific material.

For more information or assistance in selecting the perfect conveyor for your needs, don't hesitate to contact our team of experts.